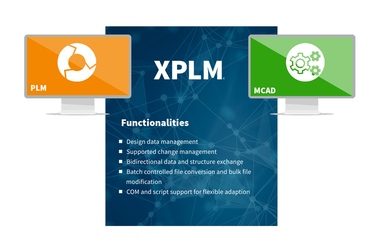

If your developers manage their design data in a PLM system, they will be more productive in many areas than with a file-based system. On top of this, an intelligent CAD PDM/PLM connector takes over routine work, controls your engineering processes and automates them where required.

Do your designers use different CAD systems at several locations? No problem. The connector combines all product and variant-describing information centrally and consistently in a data model tailored to your needs. The templates, test routines and automatisms contained therein guarantee standardised procedures and secure data handling, always from within the familiar CAD environment.

High-performance data transfers are always guaranteed, because even very large assemblies with >50,000 components are quickly loaded and saved. The collaboration management controls the collaboration of several users working on one model.

You can reinforce these positive effects on your innovation cycles by digitising the exchange of information with your other software solutions, for example for simulation and QA or with company systems such as ERP and MRP. The connectors generate all relevant data. This also works if you operate your PLM in the cloud.

Mechanical construction without routine tasks

Before a model is loaded, a search is performed. In contrast to server-based data management, the engineering-compatible search mechanisms of the CAD-PLM connectors deliver fast results, especially when the models and drawings are classified. PLM supports all MCAD objects, including in WIP status.

With large models, the file cache optimises the download. The configuration manager built into the interface offers the options "as saved", "as released" and "current" when loading. In addition, finished designs can be inserted directly from PLM into the model to be edited.

When saving CAD data, the connector receives the product's complete structure. The file is given a unique name according to your conventions. At the same time, it assigns the CAD documents material master data and a parts list. Version control prevents the accidental overwriting of existing data.

During saving, the connector triggers defined processes, for example the generation of NC files or the conversion of CAD data into any desired neutral format, individually or as a collective file, immediately or in a time-controlled batch. This means that the templates stored in the data model define which information a data package should contain.

The connector also automatically generates parts lists when a project is saved and does so in different formats. Included are a single-level, a structure and variant parts list as well as one for spare and wear parts. They can be configured for perfect results, i.e. parts can be excluded from the parts list or added manually. Data sources are either the 3D model structure or the parts list tables in drawings.

Faster to market thanks to lean processes

Item maintenance is carried out centrally in the PLM system, so that all designers always work with an up-to-date component library. After the next reconciliation, all adjustments are available to everyone involved. This reduces duplicates in the material master data and increases the reutilisation of those assemblies that have been approved.

The product lifecycle management supports sensitive processes such as approval or changes, and the CAD-PDM/PLM connector automates them. These individually defined workflows involve both the approval team and all of the information required. These flexibly adaptable processes are transparent and remain traceable.