Ansys Minerva Integration

Higher product functionality with shorter production cycles at the same time. Almost every manufacturing company is struggling with this pressure. To cope with this, simulation tools enable designs and functionality of the product to be digitally validated at an early stage of development. Through this digital prototyping, designers gain crucial insights for further product development at every stage of the creation process. This approach reduces development time and costs at the same time.

The new XPLM integration integrates ANSYS Minerva, the market-leading system for managing simulation processes and data, with your PLM systems. Stored centrally and together with the associated product data, the analyses serve (cross-domain) collaboration as well as company-wide knowledge exchange.

Sophisticated simulation processes play an essential role in the quality assurance of technical products. Native CAD data and models form the basis of calculation for stress, flow, or thermal analyses. However, without a suitable interface, transferring data from the PLM systems to Minerva is difficult. In order to completely digitalise the data streams within the engineering ecosystem, Ansys , market leader for simulation tools, and XPLM, specialist for direct integration, have joined forces as part of a technology partnership. In this way, a connection has been created between simulation and interdisciplinary design and the entire product life cycle.

- Workflow

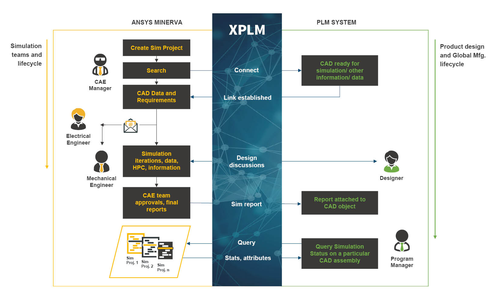

PLM data can be directly accessed from the Ansys Minerva simulation tool. With just a few mouse clicks, you are connected to the PLM system and can access all product and design data that are relevant for the simulation. - Management

Thanks to full traceability, you will be notified of changes in the adjacent systems. This enables seamless collaboration in simulation and analysis processes across Ansys Minerva and PLM systems. - Real-time data

You can search and retrieve elements from the PLM system in real time. In doing so, you can be sure that an element's latest version is always used in simulations.

Functionalities of the Ansys Minerva Integration

- Importing CAD and PLM data from PLM into Ansys Minerva

- Managing exports and imports from PLM to Ansys Minerva with Ansys Queued Solution

- Uploading simulation reports to the desired PLM objects

- Receiving notifications of changes within PLM without leaving the Ansys Minerva environment