With XSPHERE "all-in-one" taks on an new meaning

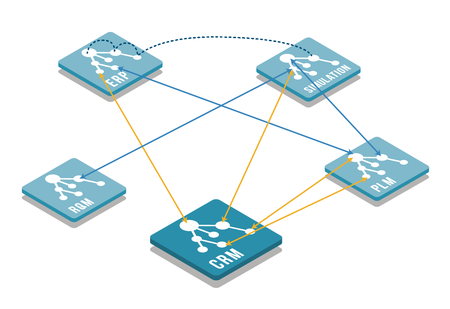

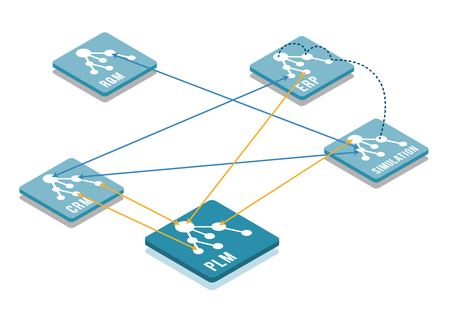

This is because the solution makes it possible for any data system in your IT landscape to establish a client connection to other systems. This allows users to access any data objects and their relationships in systems used by other departments from within their basic application. Easily, during runtime and without leaving their familiar working environment. They can view, track or edit the requested data without having to copy, synchronize or convert it first. This helps your teams make informed decisions that enable them to meet customer requirements using a collaborative, dynamic and results-oriented approach.

Your customers' departments request product improvements using a variety of different channels: in person, electronically or by talking on the phone with your technician, product manager, salesperson or someone in support. They enter the requests in the base system specific to their department. The next step is sharing the requirements with other departments so that they can be embedded in existing processes, prioritized and implemented.

XSPHERE makes it possible to link the customer's request, which is being entered in a system for the first time, with supplementary information in what is referred to as "satellite" systems. Members of the support team and developers can, for example, link the ticket or development project to the corresponding objects in the requirements management or compliance management system.

Lean basis for the digital twin and digital thread

XSPHERE overcomes the barriers of established system landscapes using state-of-the-art streaming architectures and microservices, thus making the lean structure of these cross-system, and often cross-departmental, data relationships possible . The cross-application engineering tool is integrated easily in the respective base system via an additional tab.

Your team can create meaningful data connections between a wide variety of digitally available product information, including all revisions, throughout the entire lifecycle of a product.

This gives the members of your support team direct access to the requirements stored in the requirements management tool, or Polarion, to the design and BOM data in the PLM system, to the component information in the ERP system and to the control software, e.g. in CAMEO Data Manager, from their service management environment, e.g. from Jira.

This is an ideal prerequisite for maximum transparency as well as reliable and consistent statements to stakeholders and customers, for example with regard to the path towards a solution and processing status.

Federated IT landscapes ensure that users are always up to date

Web services and microservices can be used to execute functions in the satellite system – functions that normally involve asking colleagues for help, such as searching for information using XSEARCH or comparing product versions, variants or BOMs. If a user makes changes to data in another base system, this may require action to be taken in downstream processes. This is the case, for example, if a changed requirement impacts on quality testing.

If the new specification changes the test criteria, your developers will adapt them. A federated system landscape allows them to store the new specifications with a new version number directly in the QA system. This event can trigger information being sent to the QA team. The QA team links the test procedure in its system with the project data in the PLM system. With its federated system landscape, XSPHERE not only makes the product development process transparent, it also helps design efficient and secure processes.

Real-time enterprise-wide data streaming

XSPHERE manages links that have been defined, so-called XLINKS, centrally in a table on a Microsoft Internet Information Server (IIS). It displays all the information you need, from system information such as base and satellite application with the connectors involved to the referenced data set and login information. It is obvious whether the relation is a first or second-level relation, i.e. the QA system first references the request and from there references the CAD project. The table also logs executed actions such as the user interface control elements used or the microservices called for data transformation purposes. Queries can be assigned the status "Work-in-Progress" or a version.

Easy to install, XSPHERE links databases stored in different repositories, each of which has their own mix of technologies, architectures and implementation approaches. As far as the user is concerned, however, it looks like all data is stored in a single repository.

When a user selects an object, the tool directs the connector to retrieve the data in the source system and display it in the application making the request. Regardless of whether the solution is running as an on-premise or cloud solution, it complies with the security guidelines of both applications, the base and satellite systems, when querying data. The data is subject to the full range of access rights, i.e. read, create, update and delete. Neither data models nor applications need to be adapted for XSPHERE.

Advantages of XSPHERE in a nutshell

- Users use XSPHERE from their base system

- XSPHERE establishes direct connections via API calls

- Data access is always fully audited in line with security regulations and access rights

- The individual user login manages roles and permissions

- Data is neither copied nor synchronized

- No system adaptations are needed

- Each link optimizes value added in the product creation process from the word go and again with each new call

Conclusion

Networked production and networked products such as automated or even autonomous driving and flying have long since ceased to be merely a vision. Smart systems and new, data-driven business models with new technologies like artificial intelligence and machine learning pose security-related challenges for manufacturers. Fully transparent product data and the ability to trace it are mandatory in the context of ensuring a high level of operational security.

A federated data landscape makes it easy to create a digital twin that provides information about the current configuration in the context of the task at hand. The digital "red thread", on the other hand, allows the history of all the digital information and the relationships between it to be traced throughout the entire product lifecycle. The requirements and specifications of a function are linked to its CAD models, circuit diagrams, BOMs, software and associated electronic and mechanical systems – from its first release to its as-built version.

The federated system landscape enhances close collaboration between departments, which is designed with data exchange in mind, long before the systems are put into operation. This shortens the time to market for new solutions and increases the quality of processes and products while at the same time reducing product development costs. It is not just among themselves that the developers benefit from the direct use of distributed data. Information and insights from manufacturing and service help them improve planning from the very start. Manufacturing and service are also able to work much more efficiently thanks to the fact that they can view development data and extract it for use directly on machines and assistance systems.

Those who exploit the added value of interdisciplinary collaboration via lifecycle management in a federated data landscape will remain a strong player in the market.