Fully exploit the potential of mechatronic system development

Products and systems are becoming increasingly complex. What was innovative yesterday will be standard tomorrow. Customers also prefer solutions that are tailored to meet their specific needs. This means that manufacturers need to be flexible enough to implement even last-minute adaptations reliably and precisely. This can be achieved with intelligent multi-CAD system and process solutions that map the digital thread of your products throughout their entire lifecycle. The clarity gained reduces your lead times and project costs.

In this webinar, we will show you the form these solutions can take using MCAD/ECAD collaboration in Aras Innovator as an example.

Eliminate coordination deficits and the reworking these entail

Development teams from different domains rely on different engineering concepts and methods, tools and data models. Each of our direct CAD/PLM integrations takes account of these differences. But unlike data silos for mechanical engineering, electrical engineering, electronics and software engineering, a PLM system allows you to logically link your respective product data across different domains.

All interrelationships and dependencies are indicated. This transparency is all the more important for systems with complex mechatronic structures for different drives and fluid engineering elements, sensors and photoelectric sensors through to PCBs and chips with control software.

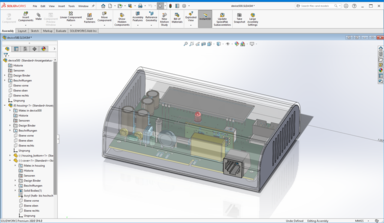

Coordination processes across different departments and companies that were previously mainly performed manually can now be controlled digitally. This means that the different teams can view their colleagues' deliverables at any time. The electronic design engineers, for example, see the mechanical housing with its interfaces for connections, drill holes and fastening screws for their PCBs. The mechanical engineers, on the other hand, see the contours of the PCB with the components that have been placed, together with their heights and the distance between them. If for example a component is too close to a housing bushing, this will detected at an early stage and corrected, thus eliminating the need for reworking entirely.

The various BOMs are extracted in line with the stored logic. A comparison of the BOMs facilitates the cross-domain plausibility check. If the two departments use one and the same component a different number of times, this is immediately apparent.

The integration's change and version management capability ensures that a new mechatronic assembly and its BOMs only include components that have already been released by the individual departments.

Incorporating downstream processes in development at an early stage

When it comes to getting products to market as quickly as possible, the teams for simulation, prototype construction and manufacturing engineering can be involved in development at an early stage via neutral formats. The multi-CAD BOM plays a key role in procurement. To avoid duplicate orders, the integration ensures that the same parts used by multiple development teams are only included in the BOM as purchased parts once.

The PLM environment also makes it easier to feed information from downstream processes back into development. If, for example, a housing contains a socket with a price of EUR 2.00 but the purchasing department prefers a comparable, less expensive component, you will immediately see whether or not the PCB assembly needs to be adapted as soon as the original socket in the housing model is replaced with the other socket.