Data streaming in a separate "base" application for user-centric processes

Are your developers spending far too much of their valuable time preparing data for other development teams, technology partners or the procurement and production departments? This doesn't have to be the case. It is possible for data consumers to query the data they need directly in the relevant data source and to do this from within their own working environment.

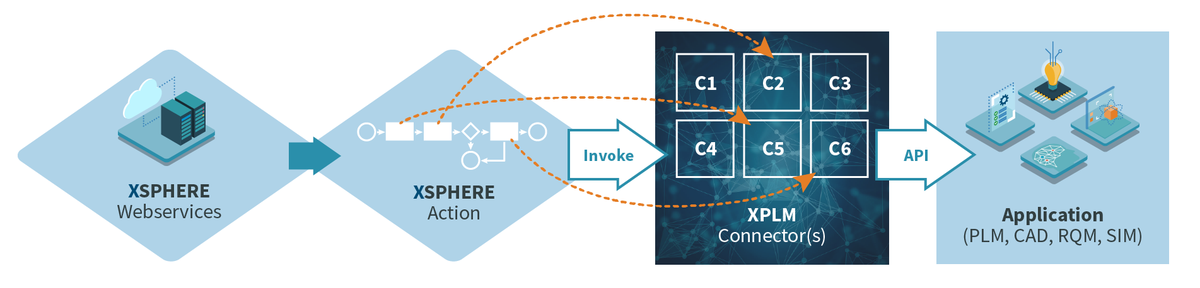

XSPHERE uses the well-established XPLM connectors to make the required information available from other data sources directly in the user's own system environment – without any need to open a second application. The queries make use of web services that can execute functions and microservices, for example a search function. They can also trigger workflows and automate processes.

Because the data is accessed directly, all this takes place in real time. It doesn't matter which source systems and structures are used to store the data relevant to a process, i.e. in the CAD, PLM, ERP or RQM system. The native data format is also of no importance.

Federated data sources increase the dynamic nature of product development

Its combination of state-of-the-art streaming architecture and microservices enables XSPHERE to deal with the complexity of established system landscapes and their data silos. Ad hoc use of data that distributed across a company makes it possible for the solution to create an agile, interlinked product development process – both internally and externally.

Data retrieval is performed without having to copy or synchronize data beforehand. Instead, the data made available references the native objects in the source system. This means that the data models in the source systems remain unchanged.

With the aid of these real-time events, which remain transparent at all times, tasks are completed faster, decisions are made based on facts, and automated business processes relieve the burden placed your employees. This creates competitive advantages.

Example: discontinuation and obsolescence management

Imagine ordering an electric motor and being told that only the successor model is available. This means that you might have to adapt the product software associated with the engine management unit and perhaps also work instructions, service procedures, the user manual, etc. The mechanical CAD model, circuit diagrams and BOMs would also have to be checked.

In the case of federated data sources that serve as a single logical source of truth, these adaptations can be made using a single roll-up function. Any adaptations performed are marked.