Requirements Management outlined using the example of a robotics project

The aim of structured requirements management is to establish a common understanding of the project within the interdisciplinary project team. It is important to take into account the different needs of stakeholders such as future users, manufacturer management, developers, quality managers, etc. Studies such as those by IAG Consulting or Standish show that a correspondingly detailed project specification helps to bring high-quality innovations to the market as planned Group. The more complex the project, the more important is a structured approach.

A manufacturer would like the bulk material provided in a container to be fed to the next processing step mechanically rather than manually. In order to evaluate the best solution for "reaching into the box " or "bin picking" , his supplier needs precise information on the task, including:

- Details of the workpieces

- What is the transport distance to be covered?

- How much space is available

- Logistics of the objects

- Target cycle time

- Production environment

Based on all the information, the process can be modeled in detail. Thus, the decision is made in favour of a linear system or a multi-axis robot and the optimal gripping technology for picking up and positioning or for the "pick & place" of the workpieces is defined. It is also clear whether a camera system is required, either to identify the position of the objects in the load carrier or for quality assurance purposes.

Transparent Requirements Lifecycle from baseline to launch

The requirements documented in the specifications describe all relevant solution details with their functions and their interdependencies. Non-functional requirements such as regulations and industry standards are also addressed.

In the robotics project, for example, the choice of container plays a role for the degree of emptying and for logistics and gripping technology, whether the workpiece is to be placed on a conveyor belt or palletized. In addition to a camera system, an additional automated system monitoring or in-line quality assurance requires appropriately programmed control software with functions specified in detail.

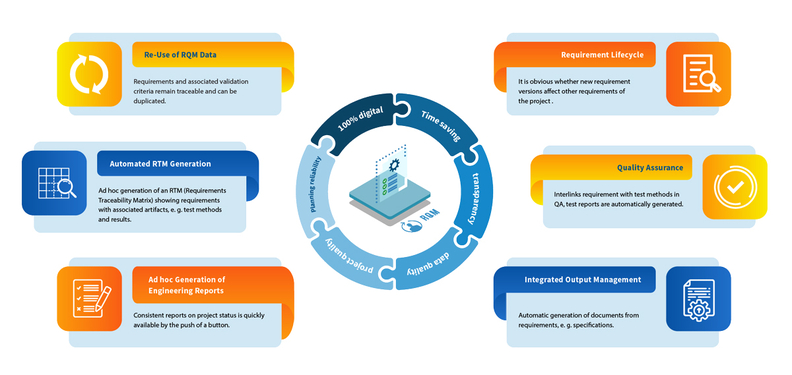

Requirements management tools and methods help to centrally manage, monitor and control these requirements and to show their lifecycle with all changes. Information silos are abolished by merging all data in different formats such as documentation, drawings and plans, photos, memos, e-mails, commercial documents, etc. in a requirements management (RQM) system and relating them to each other. This common pool of information promotes communication without misunderstandings and well-founded decisions in the interdisciplinary team. This saves time and money. This is all the more the case when requirements are reused in future projects.

Requirements and customer requests change over the course of the project. If, for example, it turns out that oil partially sticks to the workpieces, this has an effect on the gripping technique. If a suction system was previously planned, a gripper now proves to be more advantageous.

Versioned, transparently managed requirements ensure the entire team is working with valid information. In addition, a traceable change history provides a good basis for knowledge building.

Requirements Management in agile projects

Although the scope of work will certainly change as the project progresses, requirements management is just as important for agile projects as it is for the waterfall model. With the agile methodology, the product owner monitors and controls the implementation of the requirements. He updates the specifications by recording the results of the regular feedback rounds. In this way, they serve as valuable guidance for all project participants in order to define the budget and time frame.

RQM as an element of Closed Loop PLM and Digital Thread

Users of product lifecycle management (PLM) systems can link the project requirements with the product data in the PLM system and with the quality checks. In some cases, PLM platforms already include requirements management, so that relationships with the product can be established easily. In addition, PLM systems support change management, so that the relationship between requirement history and engineering versions also becomes transparent.

If system boundaries have to be overcome for such relations, they can easily be established via data federations without copying or synchronizing data. For example, XSPHERE Federation allows you to query any data in other systems from your own work environment.

Customers are satisfied when they put their new desired solution into operation on time. This objective can be achieved more easily by means of systematically planned projects. Transparent requirements management plays a central role here.