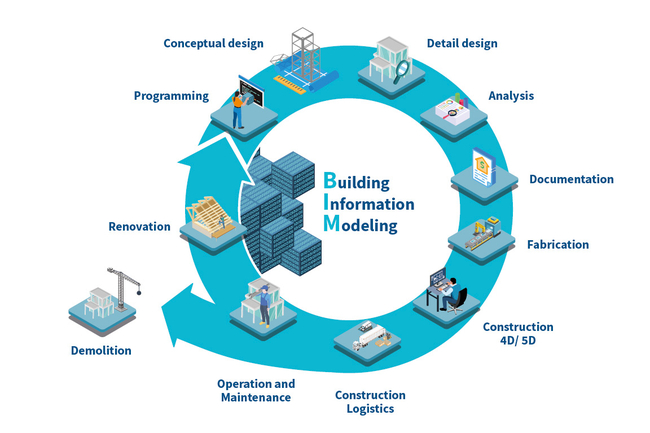

Product lifecycle management (PLM) combines data from a commercial cleaning system with a building information model (BIM)

The most important points at a glance

- Intelligent interface connects the building model with system data

- System planning based on digital plans of the technical building equipment

- Transparent life cycle management for supply technology and systems

Commercial dishwashing or professional textile cleaning is a very demanding business. Because large kitchens, for example in hotels and restaurants, as well as laundries in hospitals or, more generally, in the pharmaceutical or cosmetics industry, are subject to strict health and hygiene guidelines including safety measures such as sanitary barriers. These regulations, together with the customer's specifications for optimal operational processes, must be harmonised with the spatial conditions for supply technology.

Therefore, essential information includes not only the floor plan of the rooms to be equipped but also plans for disposal and power and material supply. Machine suppliers who need to network their devices will also be interested in IT infrastructure. As is so often the case, different planning systems with incompatible data formats hinder the interdisciplinary data exchange between building technology and mechanical engineering.

These challenges are solved by intelligent integration of building information management systems such as Autodesk Revit with systems for product life cycle management in professional cleaning systems. The bi-directional exchange of engineering data accelerates the planning process with superior planning quality. And that, in turn, reduces project costs.

Great synergy effects thanks to a common database

Architects, engineers, planning offices and construction companies use building information management systems for building planning. Together, they create a virtual 3D construction site by using the relevant information from trades close to their own work. This is how, among other things, they create plans for power, heat and water supply, for sewage and exhaust air, as well as the IT infrastructure for building automation. The special feature of BIM solutions is their ability to combine a multidisciplinary building layout in a single file. The file arranges trades in separate layers that describe circuit diagrams, piping and flow diagrams, as well as all properties and functions of the construction project.

Cleaning engineers often receive building plans from their customers as a BIM file, whereby they plan their dishwashing or textile cleaning systems. But without a corresponding license, planning partners have no way of using the trades information. And this is where the intelligent BIM-PLM interface lends a helping hand. Before storing building data in the PLM system, it divides the BIM layer model into individual trades layers and converts them separately into a neutral format such as DWG or PDF. Now designers can easily use building data to design their machines and systems and their connections. Our customer Meiko is setting a good example in that respect. They used Autodesk's BIM system Revit for room planning without an interface to Siemens Teamcenter. Without controlled data management, finding data, coordination processes and version control were difficult. Through the XPLM Revit Teamcenter integration, Revit data of Meiko 's customers and internal Autodesk data are transferred to Teamcenter and linked with NX data. Meiko thus benefits from a data model that transparently shows relationships between all project data over the entire life cycle.

Transparent life cycle of building technology and cleaning systems

If the supplier of the cleaning system starts a new project, it creates it from its familiar system environment in the PLM system. The direct integration uses the stored PLM templates to automatically generate the data model that is precisely tailored to its needs. The interface saves in a controlled manner all project information – both data provided by its customers and business partners and its own planning data – in these structures. At the same time, this data storage triggers the automatic generation of one or more parts lists. According to the stored templates, this can be, for example, a combination of a complete parts list with trade-related parts lists.

Thanks to the version control through the interface, the development history and relationships between the building and system data remain traceable over the entire life cycle. Up to the as-built version, it is clear which versions of the plans and parts lists of the building and cleaning system belong together, who created them and when, and who is responsible for the approvals. The as-built version facilitates subsequent service calls, conversions and expansions by reflecting the current situation.

Commercial dishwashing and textile cleaning systems are only examples here. The BIM-PLM integration facilitates the engineering of all systems, such as conveyor systems for elevators, production or filling processes, laboratory technology or other use-specific systems.